7 Jan 2026

FlipScreen

Out on a 100-acre property in Wagga Wagga, something extraordinary is taking shape. Not a mine. Not a city-scale factory. But a world-class manufacturing operation driven by one bold decision: to build the future of heavy engineering right here in regional Australia.

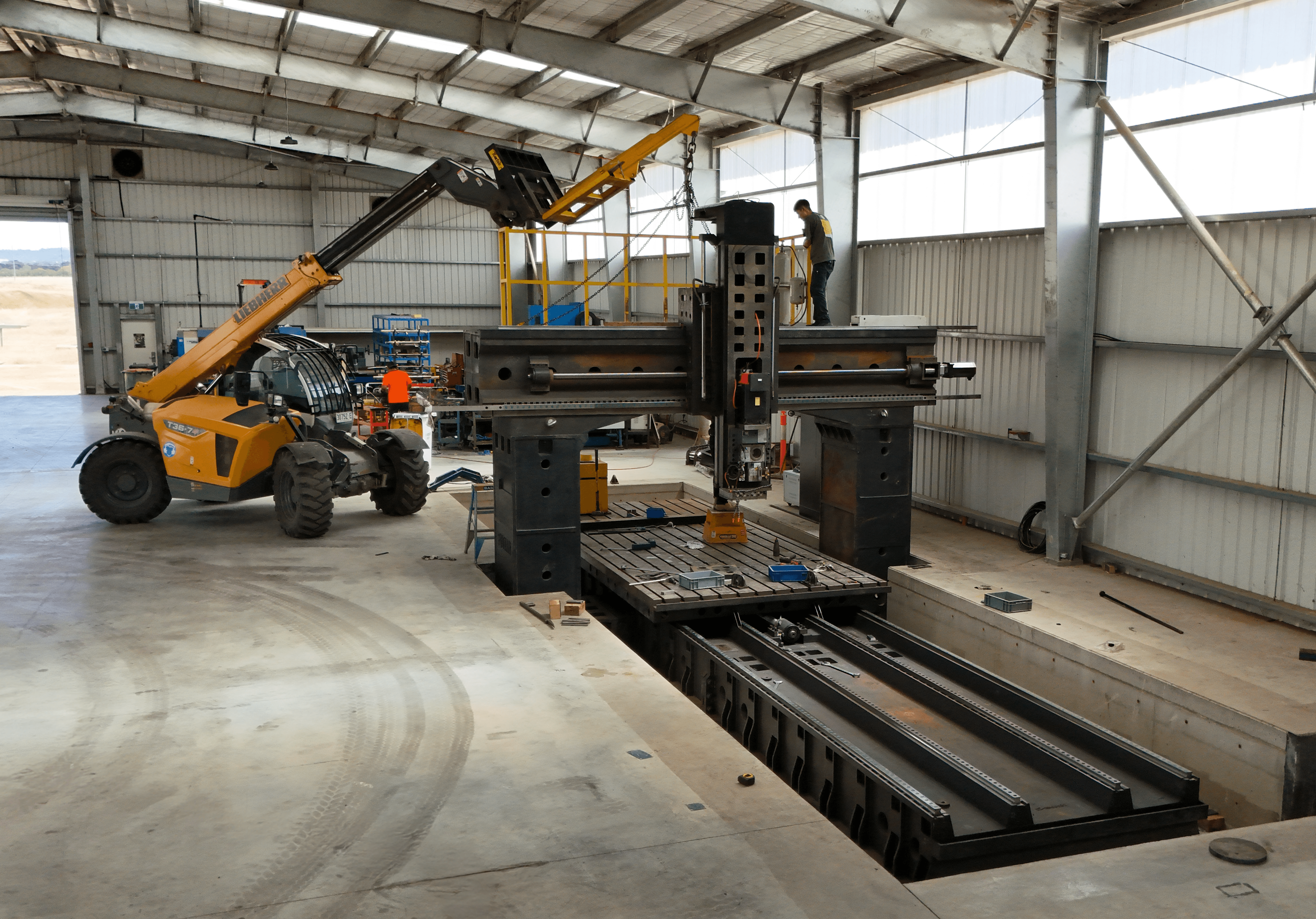

At the heart of it all now stands the biggest CNC milling machine in the district—a 68-tonne Fanuc 5-Axis Control Machining Centre. It isn’t just another piece of equipment. It’s a statement. About capability. About confidence. And about what’s possible when Australian innovation is backed by Australian manufacturing.

This engineering giant has been installed to meet the demands of one of the most ambitious machines ever built in the screening attachment world: the FlipScreen WL3000. Designed, developed, manufactured and fully integrated in Wagga Wagga, the WL3000 isn’t just the world’s largest screening bucket—it’s a product that demands a new level of precision, scale and structural integrity. And now, FlipScreen has the machine to match the vision and its Australia wide rollout.

Built for What the World Hasn’t Seen Yet

The new 5-axis machining centre is a leap forward in what can be made locally. Unlike traditional CNC machines that move in three directions, 5-axis machining allows simultaneous movement across five axes—three linear (X, Y, Z) and two rotational. In real terms, that means parts with complex geometry, tighter tolerances and fewer setup changes. Components that once required multiple operations can now be produced in a single, highly accurate pass.

The result? Faster production, higher precision, and a level of manufacturing flexibility that opens the door to continually evolving products and entirely new innovations.

For FlipScreen, this is about far more than just speed. It’s about engineering freedom. The ability to push boundaries, refine performance, and develop future innovations without outsourcing or compromise. From heavy structural components for the WL3000 to next-generation attachment designs still on the drawing board, everything can now be produced more efficiently while keeping machining under one roof.

Regional Manufacturing, Global Reach

This 68-tonne marvel sits inside one of seven new purpose-built sheds on FlipScreen’s rapidly expanding Wagga Wagga site. It’s here that the entire lifecycle of a FlipScreen product takes place - concept, design, testing, fabrication, assembly, training, and both domestic and international dispatch.

In a time when so much manufacturing has been sent offshore, FlipScreen has doubled down on keeping high-end engineering in Australia - and in a regional town. The result is skilled jobs, advanced apprenticeships, and the kind of technical career pathways that allow young people in the Riverina to build world-class machines without having to leave their home.

This is advanced manufacturing in its truest sense: cutting-edge technology, operated by highly skilled Aussies, producing equipment that competes on the global stage.

Speed, Scale and What Comes Next

The impact of the new machining centre will be felt across every part of the business. Turnaround times are set to improve significantly as large, complex components are produced faster and more efficiently. Production capacity will increase. Development cycles will shorten. Customisation and refinement will become even more achievable.

As FlipScreen continues its rapid growth both in Australia and overseas, this machine ensures that quality, control and innovation remain firmly in-house. It is not just keeping pace with demand - it is future-proofing the company’s ability to lead.

And perhaps most importantly, it reinforces what FlipScreen has always stood for: world-leading products, designed and built by Australians, in Australia.

In an era where heavy manufacturing is often seen as something we “used to do,” Wagga Wagga is proving otherwise. With 68 tonnes of cutting-edge engineering humming away in a shed on the edge of town, the message is clear: the future of advanced manufacturing is alive, well, and being undertaken at scale in the Riverina.